前漏れがありません

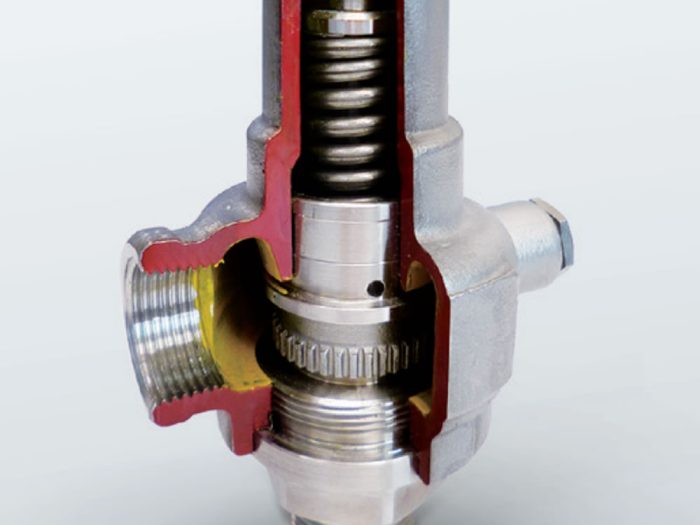

安全弁の技術的特徴

Rigid body design of the peace of mind in the improved flange structure

|

弊社の安全弁には前漏れが全くありません。弊社独自の開発した特殊技術により、前漏れの「吹き始め・吹出し同時」という現象を当ミハナ製作所が世界に先駆け成し成し遂げたのです。 Our Safety Valve allows no front-leakage thanks to the special technique developed by us. How the equipment is affected by the front-leakage is described in the following section. The phenomenon of Initial Bleeding and Blowdown occurring simultaneously is what all the Safety Valve makers have been trying to achieve and troubled by not being able to do so. We MIHANA succeed in this before any other maker in the world. |

|

「前漏れなし」の実現がお客様の安全弁を守ります。

Implementation of the “pre-leakage None” will protect your safety

安全弁には吹出し前に必ず「吹き始め」現象があり、以前は「前漏れ」と言われ、あってはいけない現象のように言われていました。この吹き始め現象(前漏れ)は、プラント内の昇圧の仕方によっては「吹き出し」までに達せず、吹き始めつまり前漏れの状態がいつまでも続き非常に危険な状態になっているにも関わらず、気づかないで放置されることにもなりかねないものです。もしこの流体が毒性ガス・可燃性ガスの場合には、大火事そして人身事故の様な大惨事を招くことになる恐れも十分に考えられます。

安全弁には吹出し前に必ず「吹き始め」現象があり、以前は「前漏れ」と言われ、あってはいけない現象のように言われていました。この吹き始め現象(前漏れ)は、プラント内の昇圧の仕方によっては「吹き出し」までに達せず、吹き始めつまり前漏れの状態がいつまでも続き非常に危険な状態になっているにも関わらず、気づかないで放置されることにもなりかねないものです。もしこの流体が毒性ガス・可燃性ガスの場合には、大火事そして人身事故の様な大惨事を招くことになる恐れも十分に考えられます。

このことは、JIS B8210において性能要求の項目で、設定圧力に「ガスに関しては吹き始めを要求」と「蒸気に関しては吹出しを要求」をしていることからも明らかで、ガス等の危険な流体に関しては設定圧力を「吹始め」と「吹出し」が同時であり前漏れを防ぐ、お客様の安全を確保することを実現しました。

As mentioned before, an initial bleeding phenomenon occurs before a safety valve starts blowing down. This initial bleeding was called front-leakage in the past and considered to be a phenomenon that should not occur. However, with the lapping technique available at the time, it was believed to be impossible to eliminate this leakage. In recent years, this is expressed as the initial bleeding in standards and regarded as an unavoidable phenomenon. However, depending on the way pressure increase in plant, the initial bleeding (front-leakage) may continue without reaching the blowdown state, resulting in an extremely dangerous condition. This dangerous condition may be left unnoticed. If the fluid happens to be a toxic gas or combustible gas, such condition may lead to a big fire or a catastrophe claiming human lives. With regard to this, JIS B 8210 specifies in its performance requirements the set pressure for the initial bleeding in case of gas and for the blowdown in case of steam. In other words, the set pressure for a dangerous fluid like gas must be set at the initial bleeding level. If the blowdown is made to occur simultaneously with the initial bleeding, the performance of a safety valve can be improved and the plant safety can be ensured. A major premise for achieving this is to improve the lapping accuracy and to eliminate any front-leakage (initial bleeding). We come to the conclusion that it must secure safety of around the equipment in which it is used. In order to satisfy this, a safety valve must be designed to permit no front-leakage to accurately start blowing down at the set pressure, to blowdown at a higher rate than the specified leave and to stop blowing down quickly (not to let out excess fluid).

動作の安定を面で作るラッピング技術

No front-leakage, Superb Lapping Technique

「バルブの命はこのシート面のラッピング技術にある」と言っても過言ではなく、人間の心臓に当たるものです。創立以来弊社のラッピング技術は、常に業界のトップにあり指導的な立場を取ってきました。

It is no exaggeration to say that the technique of lapping the seat surface determines the quality of a safety valve like the heart of human being. Since the establishment of our company, we have been the Front Runner in the industry in the development of the Lapping Technique. We will make further efforts to improve this technique through research and development.

上図のようにラッピング技術の差は、線接触と面接触の差に表れてきます。シール面圧のみを考えた場合、線接触の方が漏れにくいことになりますが、それはあくまで平面度が得られない場合のことであり、その平面度が得られるならば、線接触よりも面接触の方が漏れにくいと言うことになります。

しかも、線接触の場合適切面圧を得ることが困難であり、時間の経過あるいは作動回数が増やすごとに表面状態が破壊され、漏れが生じやすくなります。作動前に漏れが無くとも一度作動し、その線接触(シール面)がわずかでもずれた場合(実際には、同じ位置で接することは殆どないと考えてよい)当然漏れが発生することになります。

弊社の安全弁が作動させても漏れなく又敏活なホップ作動をする理由は、線接触ではなく面接触を採用しているところであるのです。そして又、精度の良い平面がえられる様になるとシート幅はより細く設計できる様になり、さらに敏活な作動性がえられる様になり、且つ又コンパクト設計も可能になってきます。

The figures above are enlarged seat surfaces shown for comparison. The different between our New Lapping Technique and the Conventional one can be seen in these, i.e. a real contact versus a lineal contact. When we think of the sealing surface pressure alone, less leakage will occur in the case of lineal contact if fine flatness cannot be achieved. If the desired fine flatness is achieved, the real contact allows less leakage. Besides, it is difficult to obtain proper surface pressure in the case of the lineal contact and with due course of time or as the number of operation times increases, the surface will be damaged, resulting in more frequent occurrence of leakage. Even if no leakage is observed before the valve is operated, if the contacting lines (sealing surface) deviate even slightly after an operation naturally leakage occurs. (In fact, the lines will seldom contact each other at the same point). This is the reason why our Safety Valve allows no leakage and performs prompt hopping actions even after repeating the operation many times is because the real contact is adopted. Furthermore, due to highly accurate surface finish, the seat width can be designed to be narrower. This permits more prompt operation and more compact valve design.

当社安全弁のシート部表面粗度は0.005ミクロンの領域です。表面粗度のみならず、表面度も他に類を見ません。これらの技術が前漏れ無し・作動耐久100回後漏れ無しをくりあしているのです。

Seat surface roughness of our safety valve is 0.005 micron region. Not only surface roughness, flatness also does not see the other kind. These are the technology is to clear the leak without before and after the leak-less – operating endurance 100 times